13

2022

-

09

He Wulei—When facing difficulties, dare to take the first step.

Author:

On the eve of the 2022 Spring Festival, affected by the COVID-19 pandemic, the production line came to a complete standstill for 33 days

On the eve of the 2022 Spring Festival, the production line came to a complete halt for 33 days due to the COVID-19 pandemic, while the deadline for the "Phase I: Strengthening Weaknesses" project was drawing ever closer.

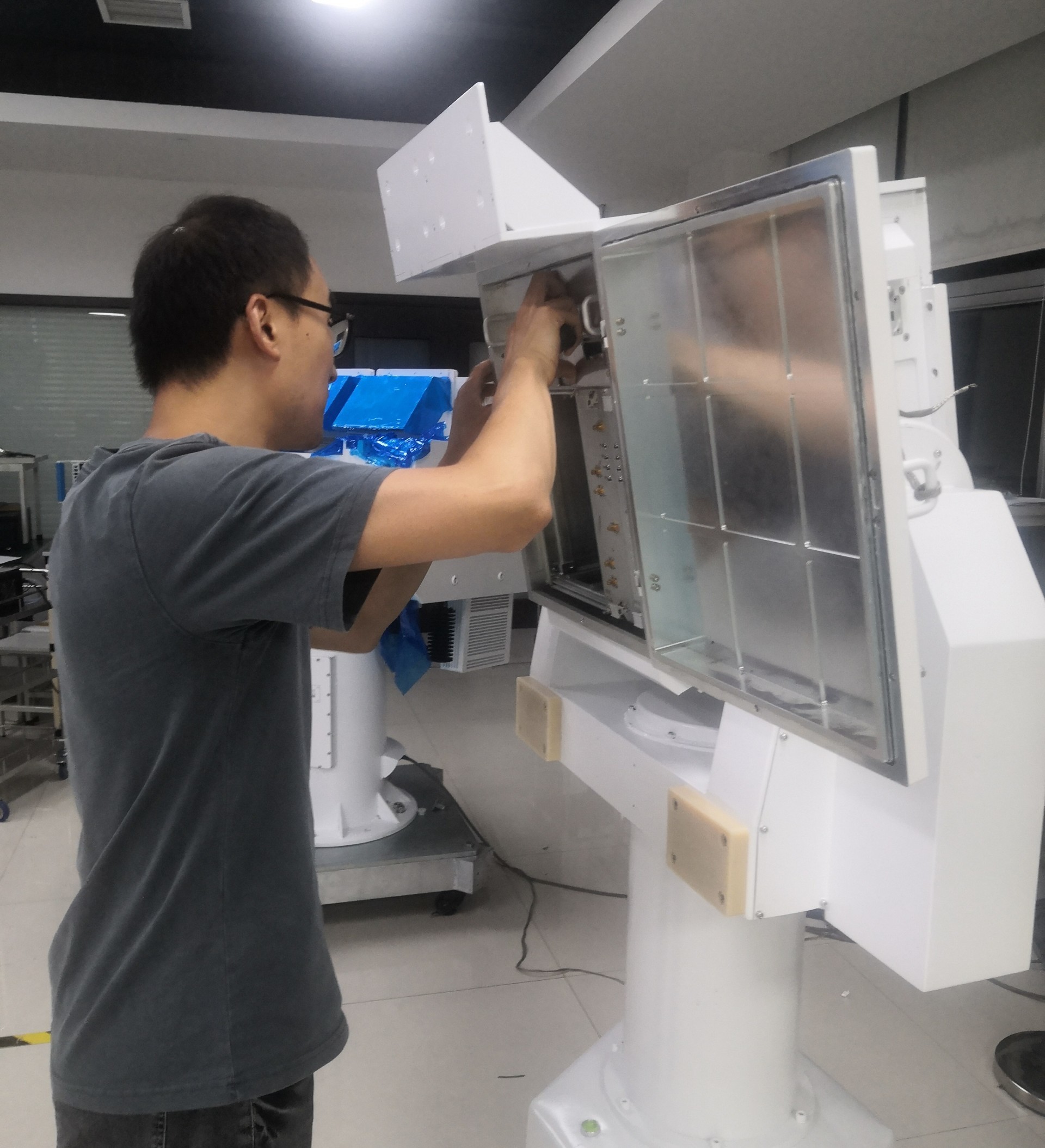

He Wulei, who served as the deputy team leader of the entire system unit, immediately jumped back into action after his quarantine was lifted. He was primarily responsible for coordinating and managing tasks such as material planning for the radar system, structural assembly, electrical installation, label application, and test verification. Given the tight project deadlines—where R&D and production were tightly intertwined and running concurrently—he often had to handle design changes and optimizations to ensure high-quality products for our customers. In mid-May, during the D-platform radar system testing conducted by R&D engineers, they discovered that the power supply ripple on the revised temperature-control board was excessively high, causing the board to malfunction. This issue not only jeopardized customer usage but also significantly increased the workload for the delivery service department’s repair operations. Upholding the principle of putting the customer first, R&D and production teams meticulously reviewed and verified the problem multiple times before ultimately deciding to implement a design modification.

At this moment, 18 complete radar units had already been manufactured on the production line—and with less than four days remaining until the customer’s scheduled site acceptance and shipment. Upon receiving the rework notification, He Wulei’s immediate reaction was how to boost efficiency while ensuring top-notch product quality. First, he coordinated with R&D personnel to revise the power supply wiring and structural design documents for the temperature-control board modifications. He then promptly began breaking down the revised plan, clearly communicating each step to team members responsible for wiring, assembly, and debugging across all relevant roles. At the same time, he meticulously drafted a detailed daily production schedule and took the lead by working overtime late into the night every day. Together with his team, he successfully completed the dismantling, modification, and structural reconfiguration of the temperature-control system cables for all 18 radar units within just three days. Ultimately, the products passed inspection flawlessly, allowing the company to meet the deadline and fulfill the "Phase I Shortfall Remediation" task for the complete radar units—thus upholding the core value of "customer first."

There is no success achieved overnight—every accomplishment is steeped in the sweat of hard work. Recalling the scene at the time, He Wulei still looks back with unwavering determination: "This was a task that seemed impossible to complete back then, but I knew that 'Ensuring quality, maintaining quantity, and delivering on time' wasn’t just a slogan—it was our solemn vow to our products, our company, and our customers. And I firmly believe that as long as we’re willing to put in the effort, we’ll surely succeed. As it turns out, that’s exactly what happened."

Testing,Temperature control

Annual Gala | Auspicious Dragon Brings in Spring, Huateng Soars on the Wind

As the Auspicious Dragon ushers in spring, HuaTeng soars boldly on the winds of change

2024-02-03

The camp is officially open! HuaTeng Microwave's "Young Seed Training Camp" kicks off today!

To continuously build a dynamic organization, cultivate outstanding talent, and develop a strong pipeline of future leaders

2023-12-20